The evolution of auto dent repair technology has shifted from labor-intensive manual processes to advanced solutions, including pneumatic tools, laser sensors, CAD software, robotic systems, and digital innovations like Paintless Dent Repair (PDR). These advancements not only enhance the quality and consistency of repairs but also reduce environmental impact by minimizing material waste, energy consumption, and waste generation. Modern auto repair shops leverage these technologies to provide faster, more cost-effective, and high-quality auto dent repair services.

The world of auto dent repair has undergone a remarkable transformation, evolving from traditional methods to state-of-the-art techniques that have revolutionized the industry. This article explores the advanced technology shaping modern dent repair practices. From the historical foundations to cutting-edge innovations, we delve into the tools, techniques, and materials that enable efficient, precise, and sustainable auto dent repairs. Discover how these advancements are redefining the landscape of vehicle restoration.

- The Evolution of Auto Dent Repair Technology

- – A brief history of dent repair methods

- – Transition from traditional to advanced techniques

The Evolution of Auto Dent Repair Technology

The evolution of auto dent repair technology has been nothing short of remarkable, transforming a once labor-intensive and time-consuming process into a highly efficient and effective procedure. In the past, car dent repair involved manual labor, with skilled technicians using hammers and chisels to carefully remove dents, often resulting in lengthy processes and potential damage. However, the advent of advanced technologies has revolutionized this industry.

Today, auto dent repair shops employ state-of-the-art equipment like pneumatic tools, laser sensors, and computer-aided design (CAD) software. These innovations enable precise measurements and accurate repairs, minimizing the need for excessive material removal. Additionally, robotic systems have been introduced to enhance speed and consistency, making tire services and car scratch repair more accessible and affordable. This evolution has not only improved the quality of car repair services but also reduced the environmental impact by minimizing waste and energy consumption compared to traditional methods.

– A brief history of dent repair methods

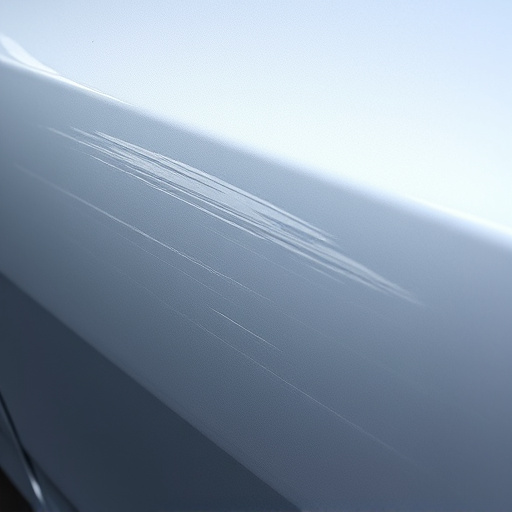

The art of auto dent repair has evolved significantly over time, reflecting the technological advancements that have permeated the automotive industry. Historically, repairs often involved laborious and imprecise methods, with technicians using hammers and chisels to manually remove dents. This process was time-consuming and could lead to visible evidence of the repair, such as metal marks or uneven surfaces. As technology progressed, so did the tools and techniques employed in auto dent repair. The introduction of specialized equipment like pneumatic hammer tools and heat guns marked a step towards faster and more efficient repairs.

In recent years, the digital revolution has completely transformed the landscape of auto dent repair. Paintless dent repair (PDR) techniques have gained prominence, offering precision and minimal interference with the vehicle’s original paint job. PDR uses specialized tools to access and remove dents from the inside of the panel, leaving little to no trace of damage. This method is not only faster but also cost-effective for many auto body shops, providing high-quality auto repair services without extensive repainting or reworking.

– Transition from traditional to advanced techniques

The auto dent repair industry has undergone a remarkable transformation over the years, transitioning from traditional methods to advanced techniques that have revolutionized vehicle restoration. In the past, repairs often involved manual labor, where skilled technicians would meticulously use hammers and putty knives to reshape metal and remove dents. This process was time-consuming, required significant expertise, and sometimes left visible traces of the repair.

However, with advancements in technology, auto dent repair has become more precise and efficient. Modern auto repair shops now employ advanced tools such as computer-aided design (CAD) software, robotic arms, and state-of-the-art paint systems. These innovations enable technicians to accurately assess damage, make precise cuts, and seamlessly blend repairs with the existing car paint, resulting in a virtually indistinguishable restoration. The shift towards these advanced techniques has not only improved the quality of auto dent repair but also reduced the time and cost associated with vehicle repair.

The evolution of auto dent repair technology has transformed the industry, offering faster, more efficient, and precise solutions compared to traditional methods. Advanced techniques like laser repairs, robotic painting, and 3D printing not only enhance aesthetics but also streamline the process, reducing costs and time. As technology continues to advance, we can expect even more innovative auto dent repair methods, ensuring vehicles return to their pre-incident condition swiftly and effectively.